Blog

January 22, 2020

FDA Design Controls: Medical Device Developer Guide

Application Lifecycle Management,

Security & Compliance

FDA regulations for medical devices are strict, complex and lengthy. Here’s a plain and simple version of design controls for medical device development to help you understand FDA design controls for medical devices. Plus best practices for implementing design controls as productively as possible.

This blog will cover all of the topics below. Read along or jump to the topic that interests you most:

Table of Contents

- What Are FDA Design Controls: Medical Device?

- FDA Design & Development Planning: How to Do It

- What Are Design Inputs and Design Outputs?

- What Is a Design Review?

- FDA Design Verification: How It Works

- Design Validation: How It Works

- Design Transfer: How It Works

- Design Changes: How It Works

- What Is a Design History File (DHF)?

- How to Improve Your Medical Device Design Controls Process

What Are FDA Design Controls: Medical Device?

The design control process follows a set of practices and procedures that help medical product developers:

- Manage quality.

- Ensure each product meets all requirements.

- Prevent potential issues or recalls in the future.

FDA Design Controls for Medical Device

Design controls for medical devices are regulated by the FDA under 21 CFR 820.30. They must be implemented by manufacturers of class II or III medical devices (and some class I devices).

Outside of the U.S. a set of very similar regulations (nearly exactly the same, actually) are dictated by ISO 13485:2016. So, to keep things as simple as possible, we’ll focus on the FDA guidelines here.

Medical design control stages from both the FDA and the ISO consist of:

- Design & development planning.

- Design inputs.

- Design outputs.

- Design review.

- Design verification.

- Design validation.

- Design transfer.

- Design changes.

- Design history file.

The regulations define each stage in a linear fashion. But each requirement is actually a part of a dynamic process that can change and repeat. This is known as the design and development planning model.

Back to topFDA Design & Development Planning: How to Do It

How do you go about designing & developing your device? Design and development planning covers exactly that.

According to section 820.30(b) of the FDA guidance, design and development planning requires:

- Each manufacturer shall establish and maintain plans that describe or reference the design and development activities and define responsibility for implementation.

- The plans shall identify and describe the interfaces with different groups or activities that provide, or result in, input to the design and development process.

- The plans shall be reviewed, updated, and approved as design and development evolves.

Put Plainly

This control stage requires developers to clearly layout their entire process. This documents exactly:

- What will be made.

- How each piece will be created and tested.

- Who will be in charge of making those things happen.

The length and detail of your design planning activities will depend on the product you’re planning to make and size of your organization. Most importantly, this stage requires developers to maintain their design and development plan as the process goes on. So, any changes to the original plan need to be tracked and documented.

Design Planning Insight

There are many key questions that need to be answered during this stage:

What major deliverables are there? How long will they take? Who will be responsible for what? What are key tasks & time constraints? When will reviews be made, and who will make them? How will all of these things be documented?

It can feel overwhelming but documenting all of these things now will save you a lot of headaches. And it will ensure that your team is above reproach in the future.

📘Related resource: The State of Medical Device Development

Back to topWhat Are Design Inputs and Design Outputs?

Design Inputs

Design inputs are typically the device requirements (both physical and performance) describing the medical device you’re going to make.

Section 820.30(c) of the FDA guidance says:

- Each manufacturer shall establish and maintain procedures to ensure that the design requirements relating to a device are appropriate and address the intended use of the device, including the needs of the user and patient.

- The procedures shall include a mechanism for addressing incomplete, ambiguous, or conflicting requirements.

- The design input requirements shall be documented and shall be reviewed and approved by designated individual(s).

- The approval, including the date and signature of the individual(s) approving the requirements, shall be documented.

Put Plainly

You’ll need to define:

- What the device does for the end user & patient (functional requirements).

- How it works (performance requirements).

- How the device will work with other systems (interface requirements).

These definitions need to be approved by the people outlined in your design planning document. Any changes made as a result of verification or validation (testing activities, covered later) will also need to be documented.

Design Input Insight

This part is difficult and can become complex. In fact, it can take up to a third of your total project time! But setting requirements will make or break product success, so it’s important to get them right.

They’re also the lowest-cost place to make changes. During later phases, a change will delay development and require more person power to achieve. To stay on track, ensure design inputs are clear, concise, and complete.

Design Outputs

Design outputs are the final results of the all the design and engineering work. They’re usually represented in models, drawings, engineering analysis, and other documents.

Design output requirements, according to FDA 820.30(d) are as follows:

- Each manufacturer shall establish and maintain procedures for defining and documenting design output in terms that allow an adequate evaluation of conformance to design input requirements.

- Design output procedures shall contain or make reference to acceptance criteria and shall ensure that those design outputs that are essential for the proper functioning of the device are identified.

- Design output shall be documented, reviewed, and approved before release.

- The approval, including the date and signature of the individual(s) approving the output, shall be documented.

Put Plainly

Design outputs are the documents that you would give to manufacturers to make the device and its component. Basically, if you listed it as a work item or deliverable in the design & development plan (covered earlier), then it is a design output. And, just like design inputs, outputs need to be reviewed and approved by stakeholders (with signatures).

Design Output Insight

Tracking work items through the development process can be challenging. Establishing traceability makes it easier to track work items, such as design outputs.

Back to topEvaluating Requirements Management Solutions?

Learn the 5 questions companies in highly regulated industries must ask when comparing traceability and compliance solutions. Download our Requirements Management Software Buyer's Guide.

What Is a Design Review?

The design review is a formal review of the medical device design.

FDA requirements for design review, according to 820.30(e), include the following.

- Each manufacturer shall establish and maintain procedures to ensure that formal documented reviews of the design results are planned and conducted at appropriate stages of the device’s design development.

- The procedures shall ensure that participants at each design review include representatives of all functions concerned with the design stage being reviewed and an individual(s) who does not have direct responsibility for the design stage being reviewed, as well as any specialists needed.

- The results of a design review, including identification of the design, the date, and the individual(s) performing the review, shall be documented in the design history file (the DHF).

Put Plainly

The main question you’re asking during design reviews is: Are you sure this is right? After putting together designs and discovering any problems that will or may occur, you need to confirm the design is right and buildable.

If it’s not, you’ll raise concerns and put forth a plan of action. Design reviews should take place during all phases of device development.

Design Review Insight

You can get the most out of your design reviews by being strategic about your reviewers. Make sure they are qualified and have the right mix of expertise. And make sure you’re always including someone who can bring a fresh, objective view.

Back to topFDA Design Verification: How It Works

During design verification, you make sure design output conforms to design input.

Under 820.30(f) of FDA guidelines:

- Each manufacturer shall establish and maintain procedures for verifying the device design.

- Design verification shall confirm that the design output meets the design input requirements.

- The results of the design verification, including identification of the design, method(s), the date, and the individual(s) performing the verification, shall be documented in the Design History File.

Put Plainly

Did you build the device correctly? Design verification also confirms that what you’ve built is exactly the way that you planned it. So, this stage involves a lot of testing of components at various stages throughout the development process.

Design Verification Insight

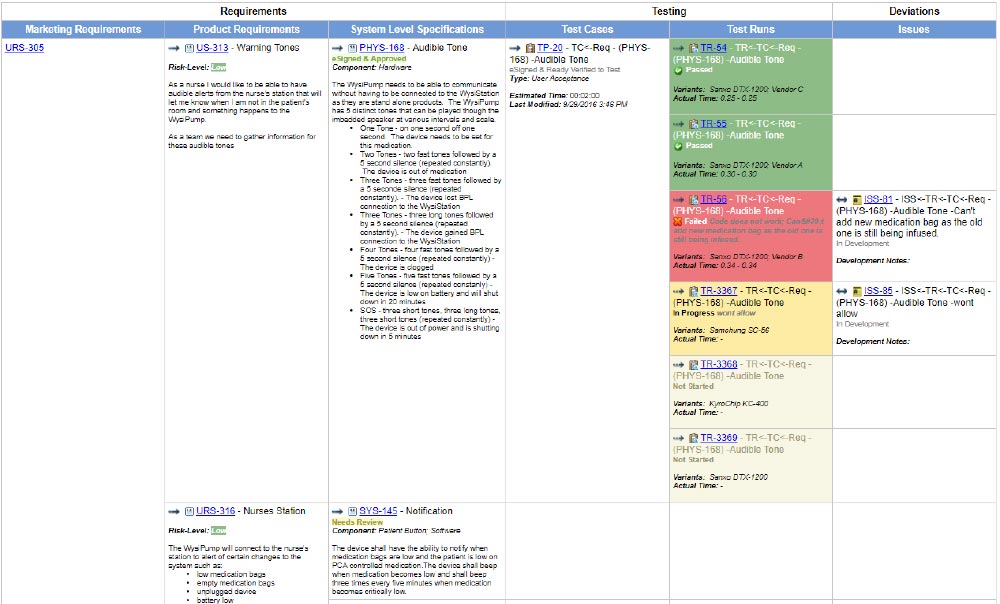

A traceability matrix, which connects design inputs (requirements) to their related issues and tests, will be critical in verifying your device. While you can create a matrix using spreadsheets or similar, many device developers use specialized ALM tools to generate them automatically.

Learn how Fractyl achieved compliance in record time — read the case study >>

Back to topDesign Validation: How It Works

During design validation, you ensure the device meets needs of users and satisfies its intended use.

Section 820.30(g) defines design validation.

- Each manufacturer shall establish and maintain procedures for validating the device design.

- Design validation shall be performed under defined operating conditions on initial production units, lots, or batches, or their equivalents.

- Design validation shall ensure that devices conform to defined user needs and intended uses and shall include testing of production units under actual or simulated use conditions.

- Design validation shall include software validation and risk analysis, where appropriate.

- The results of the design validation, including identification of the design, method(s), the date, and the individual(s) performing the validation, shall be documented in the Design History File.

Put Plainly

Does it work? In design validation, you’re putting the actual product through the test and making sure it does what you said it would do. That means you’ll put it in its expected environment (or simulation of the environment) and see what happens. Here you’re testing packaging, transport, and more for anyone who may come into contact with your end product.

Deficiencies will need to be addressed. Risk analysis is key as in some cases deficiencies will fall into a wide range. Some will be critical. Others won’t. You’ll need to decide what needs to be addressed. Everything needs to be put in your design history file, which we’ll cover later.

Design Validation Insight

Have a solid plan upfront and loop everyone in. Include test engineers early in development planning to make sure requirements and design are clear, complete, and testable. That way, you can uncover technology issues before they become obstacles.

Back to topDesign Transfer: How It Works

Design transfer is how you translate the device design into production, distribution, and installation specifications.

Section 820.30(h) from the FDA guidelines explains design transfer.

- Each manufacturer shall establish and maintain procedures to ensure that the device design is correctly translated into production specifications.

Put Plainly

You need to make sure that those making, moving, and installing the device have everything they need to do their job correctly. And you need to set up plans and processes to do that.

Design Transfer Insight

Knowing your audience is critical here. You need to ensure the specs are provided using the right format and to the level of detail that others will need to achieve this. For example, a skilled artisan is going to need a different kind of spec than a contracted manufacturer with little professional experience or knowledge.

Back to topDesign Changes: How It Works

Design changes is the process by which changes to design are identified and documented.

820.30(i) from the FDA guidelines explain design changes.

- Each manufacturer shall establish and maintain procedures for the identification, documentation, validation or where appropriate verification, review, and approval of design changes before their implementation

Put Plainly

What changed? When and why? And who approved those changes? For managing the design changes element of design controls, you need to make sure you have all of these changes and decisions tracked.

Design Transfer Insight

Two key elements here are:

- Document control (good file structure, revision history, etc.).

- Change control (documentation of change requests and change orders).

Make sure that these things are planned and implemented early on so that every change is easier to understand.

Back to topWhat Is a Design History File (DHF)?

The DHF is a formal document, prepared for each medical device, that contains all of the required documents from the earlier stages. It’s either a collection of the actual documents generated during product development or an index of documents and their storage location.

The FDA defines the design history file in section 820.30(j):

- Each manufacturer shall establish and maintain a DHF for each type of device.

- The DHF shall contain or reference the records necessary to demonstrate that the design was developed in accordance with the approved design plan and the requirements of this part. Cross-reference to ISO 9001:1994

Put Plainly

Nearly every single design control element contains some activity that needs to be documented. All of this goes into the design history file. By the time your product is shipped, you should have an organized account of how that product came to be.

Design History File Insight

It’s important to have these requirements and your design control process clearly laid out. And it should be agreed upon early on. These are vital to the creation of a detailed DHF.

Back to topHow to Improve Your Medical Device Design Controls Process

FDA regulations may be complicated, but your design control process doesn’t need to be. Using Perforce ALM (formerly Helix ALM) can help you take control of your medical device development.

See for yourself how Perforce ALM improves the design control process. Try it free for 30 days or watch the product demo.